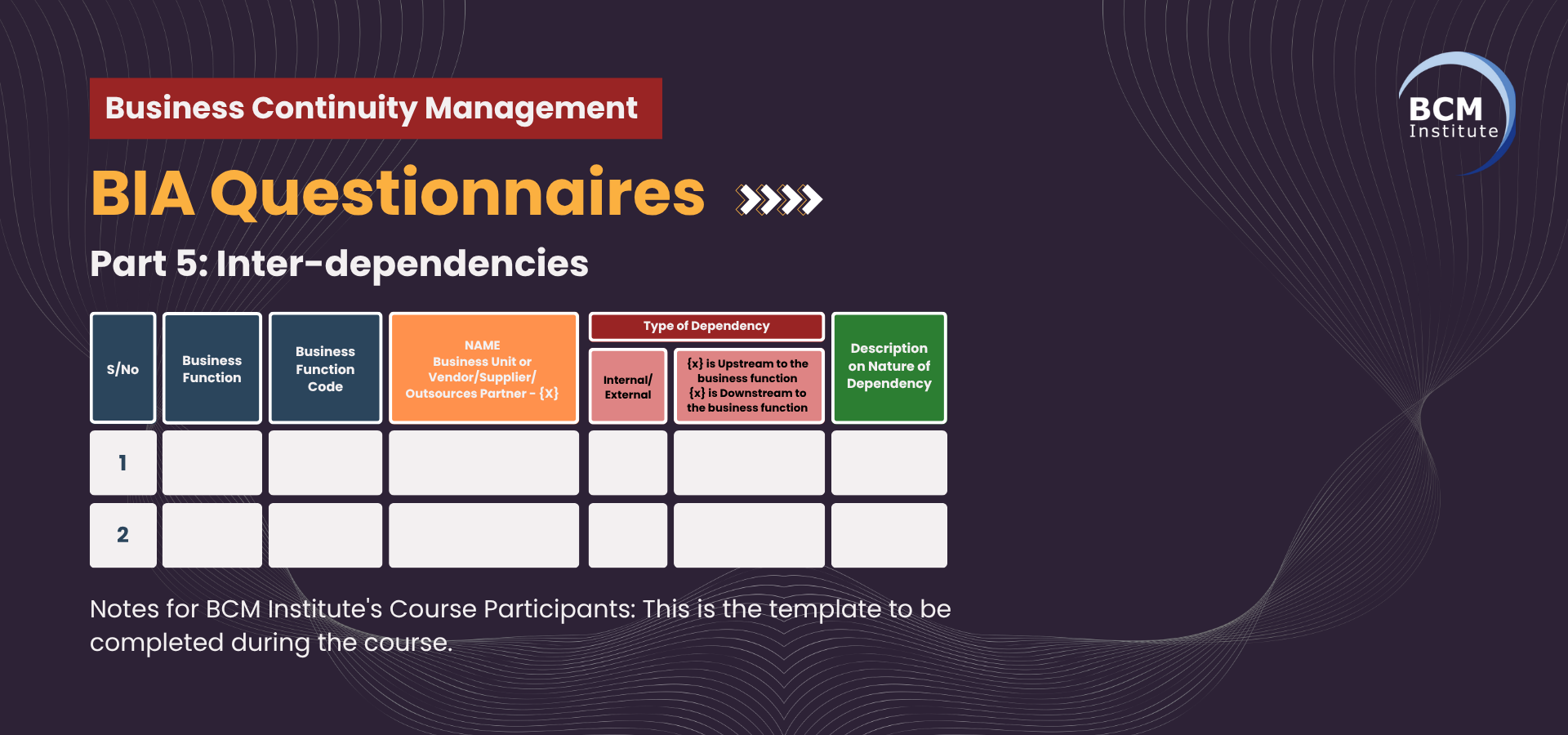

[Business Impact Analysis] [Critical Business Function] [T3] Part 5

BIA Questionnaires

Part 5: Inter-dependencies

CBF-2 Manufacturing and Assembly Operations

Manufacturing and assembly operations at ASMPT are highly complex and interconnected, involving multiple business units, technology platforms, and external partners across the semiconductor and electronics supply chain.![[BCM] [ASMPT] [E3] [BIA] [T3 [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/7283dbc8-f3df-4254-99f1-f7ec89c71f08.png)

The effectiveness of these operations depends not only on internal coordination across specialised processes but also on timely inputs from suppliers, equipment vendors, and outsourced partners.

Inter-dependencies can be categorised as internal (between ASMPT’s own business units), external (with suppliers, vendors, and partners), and by direction of dependency:

- Upstream dependency: Inputs or resources required before a process can proceed.

- Downstream dependency: Outputs delivered to subsequent processes or customers.

- Mutual dependency: Continuous exchange of inputs and outputs between two or more parties.

Understanding and mapping these inter-dependencies is critical for business continuity management under ISO 22301.

It ensures that any disruption in one sub-CBF does not cascade into prolonged downtime across ASMPT’s manufacturing ecosystem.

Table: Inter-dependencies for

CBF-2 Manufacturing and Assembly Operations

|

Sub-CBF Code |

Sub-CBF |

Name of Business Unit or Vendor/ Supplier/ Outsource Partner |

Type of Depend-ency - Internal |

Type of Depend-ency - External |

Depend-ency Direction |

Description of the Nature of Dependency |

|

1.1 |

Wafer-Level Preparation & Substrate Processing |

ASMPT Materials Engineering, Wafer & Substrate Suppliers |

Yes |

Yes |

Upstream |

Relies on material engineering for specifications and on suppliers for high-quality wafers and substrates. |

|

1.2 |

Die Attach & Flip-Chip Bonding |

ASMPT Bonding Systems Unit, Adhesive & Solder Paste Vendors |

Yes |

Yes |

Upstream & Downstream |

Internal bonding systems design integration; external adhesives and solders required for attachment processes. |

|

1.3 |

Deposition & Metallization |

Thin-Film Equipment Vendors, ASMPT Equipment Engineering |

Yes |

Yes |

Mutual |

Equipment calibration (internal) and external thin-film equipment vendors ensure precise metallization processes. |

|

1.4 |

Molding, Trimming & Forming |

Packaging Unit, Mold Compound Suppliers, Outsourced Mold Services |

Yes |

Yes |

Downstream |

Internal packaging unit alignment and external mold compound supply critical for product encapsulation. |

|

1.5 |

Assembly & Sensor Integration |

ASMPT Sensor Division, Third-Party Sensor Suppliers |

Yes |

Yes |

Mutual |

Internal assembly teams align with ASMPT’s sensor design; external suppliers provide specialized sensor chips. |

|

1.6 |

In-Line System Integration & Automation |

ASMPT Automation Unit, Robotics Vendors |

Yes |

Yes |

Downstream |

Dependent on internal automation expertise and external robotics vendors for system-level integration. |

|

1.7 |

Smart Factory Integration & Open Automation |

ASMPT Digital Transformation, IoT Platform Vendors |

Yes |

Yes |

Mutual |

Requires integration of internal digital systems and external IoT platforms for seamless factory operations. |

|

1.8 |

Process Monitoring, MES & Data Analytics |

ASMPT IT & Data Analytics, MES Software Vendors |

Yes |

Yes |

Upstream & Downstream |

Internal IT ensures MES deployment, while external vendors provide software support and updates. |

|

1.9 |

Quality Assurance & End-of-Line Handling |

QA Unit, Testing Equipment Vendors, Logistics Partners |

Yes |

Yes |

Downstream |

Internal QA ensures standards; external test equipment vendors and logistics partners enable product shipment |

This table distinguishes internal vs. external dependencies, shows whether each is upstream, downstream, or mutual, and explains the nature of dependency clearly.

Summing Up ... Part 5

The inter-dependencies of SMFSC’s Casework & Counselling function highlight the organisation’s reliance on a network of internal teams and external stakeholders to deliver effective client outcomes.

These linkages are not only operational but also strategic, as they reinforce the centre’s commitment to holistic care, regulatory compliance, and community collaboration.

Understanding whether a dependency is upstream, downstream, or mutual allows SMFSC to prioritise continuity planning, allocate resources, and strengthen coordination with critical partners.

Ultimately, recognising and managing these inter-dependencies enhances resilience, ensures service continuity during disruptions, and reinforces SMFSC’s role as a trusted provider of essential social support services in the community.

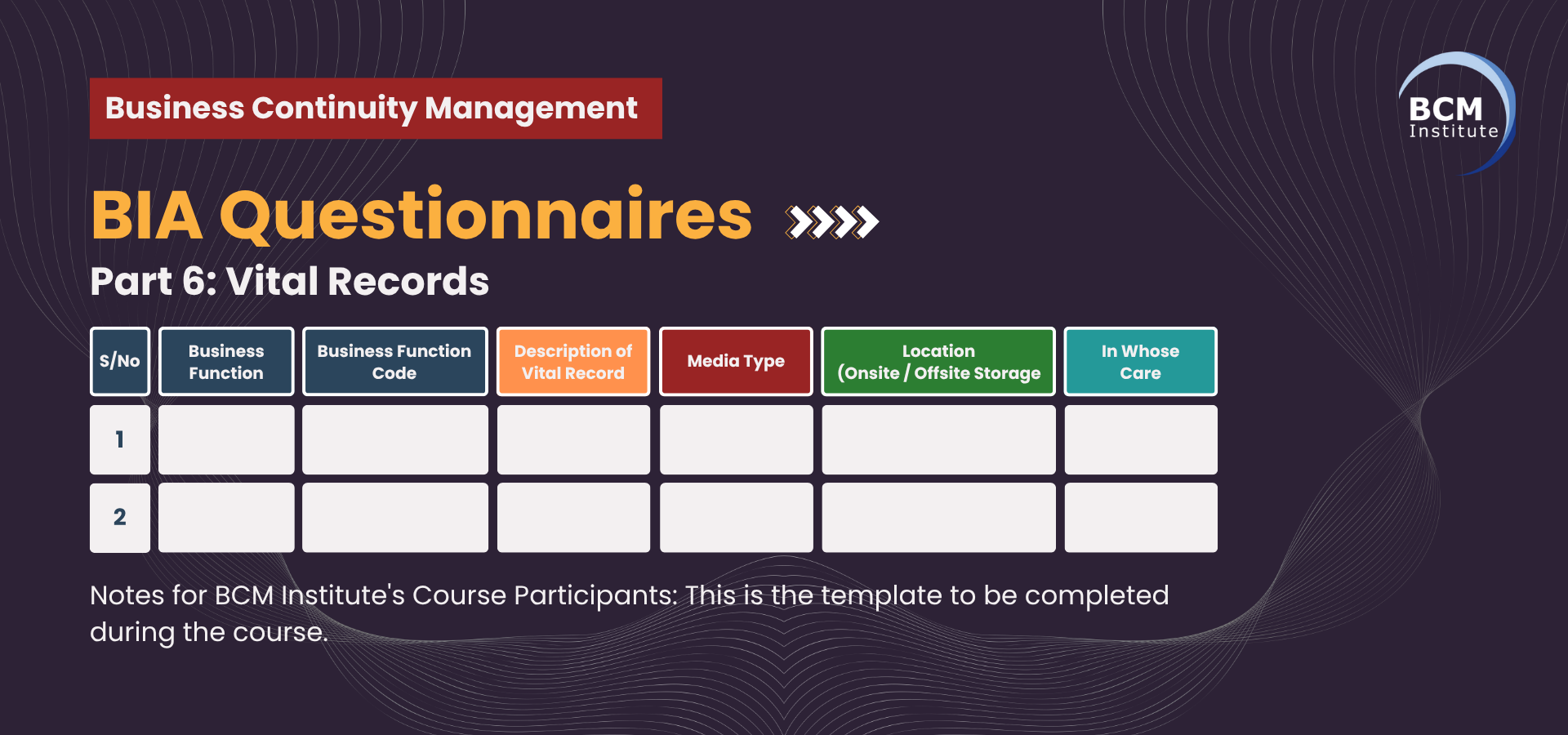

[Business Impact Analysis] [Critical Business Function] [T3] Part 6

BIA Questionnaires

BIA Questionnaires

Part 6: Vital Records

Part 6: Vital Records

CBF-2 Manufacturing and Assembly Operations

Vital records are the essential documents, data, and information that enable an organisation to maintain continuity of operations during and after a disruption.

For ASMPT’s Manufacturing and Assembly Operations (CBF-2), these records safeguard the ability to resume production, meet customer commitments, and comply with regulatory requirements.

In the context of semiconductor and electronics assembly, vital records extend beyond conventional financial or HR documentation.

They include production specifications, process recipes, machine calibration data, system integration protocols, and quality control certifications.

These records must be protected, retrievable, and secured in multiple formats and locations to mitigate operational risk.

The following table outlines the vital records required for each Sub-CBF under CBF-2 Manufacturing and Assembly Operations, specifying their description, media type, location, and custodianship.

Vital Records Table

|

Sub-Critical Code |

Sub-CBF |

Description of Vital Records |

Media Type |

Location |

In Whose Care |

|

1.1 |

Wafer-Level Preparation & Substrate Processing |

Process design specifications, wafer handling procedures, substrate recipes, and equipment calibration records |

Electronic (ERP/MES), Hard Copy |

Data Centre, Engineering Office |

Process Engineering Manager |

|

1.2 |

Die Attach & Flip-Chip Bonding |

Bonding parameters, die attach programs, flip-chip alignment profiles, and machine qualification logs |

Electronic (MES), Hard Copy |

Cleanroom Server, Production Office |

Production Supervisor |

|

1.3 |

Deposition & Metallisation |

Deposition recipes, metallisation thickness records, chemical usage logs, equipment safety certificates |

Electronic (LIMS, MES), Hard Copy |

Data Center, Chemical Storage Facility |

Materials Scientist / Facilities Manager |

|

1.4 |

Moulding, Trimming & Forming |

Mould designs, trimming tool specifications, forming process settings, and maintenance logs |

Electronic CAD files, Hard Copy |

Tooling Room, Design Server |

Tooling Engineer |

|

1.5 |

Assembly & Sensor Integration |

Assembly blueprints, integration guidelines, sensor calibration data,and customer assembly specifications |

Electronic (ERP/MES), Hard Copy |

Assembly Floor, Customer Document Repository |

Assembly Engineering Lead |

|

1.6 |

In-Line System Integration & Automation |

PLC programming files, automation workflows, robotics configuration records, system integration diagrams |

Electronic (SCADA, PLC files), Hard Copy |

Automation Lab, Control Room |

Automation Systems Engineer |

|

1.7 |

Smart Factory Integration & Open Automation |

Smart factory architecture documentation, IoT sensor network maps, API interface records |

Electronic (Cloud Storage, MES), Hard Copy |

IT Data Center, Cloud Repository |

Digital Transformation Manager |

| 1.8 |

Process Monitoring, MES & Data Analytics |

MES configuration, process monitoring dashboards, analytics algorithms, real-time performance data logs |

Electronic (MES, Database) |

Data Center, Backup Data Repositories |

IT Applications Manager |

| 1.9 |

Quality Assurance & End-of-Line Handling |

Test protocols, inspection checklists, defect tracking logs, certification reports (ISO, customer-specific) |

Electronic (QMS, MES), Hard Copy |

QA Office, Secure Archive |

Quality Assurance Manager |

Summing Up ... Part 6

Vital records serve as the backbone of ASMPT’s Manufacturing and Assembly Operations (CBF-2), ensuring that essential production processes can be restarted swiftly and accurately following a disruption.

By safeguarding key documents—ranging from wafer specifications to automation workflows—ASMPT strengthens its resilience against operational downtime, regulatory non-compliance, and reputational risks.

Proper custodianship, redundancy in storage, and clear assignment of responsibility guarantee that vital records remain secure, accessible, and usable when needed most.

In line with ISO 22301 best practices, this structured management of vital records enables ASMPT to uphold both business continuity and its commitment to customers in the highly demanding semiconductor industry.

![[BCM] [ASMPT] [E3] [BIA] [DP] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/449872f6-6f44-40f2-96ad-16b26b246176.png)

![[BCM] [ASMPT] [E3] [BIA] [T1] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/ea7d252e-53e6-4fd2-8bd9-5a9baa0dd532.png)

![[BCM] [ASMPT] [E3] [BIA] [T2] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/93203b93-22b9-4134-8a90-52f0be30fc37.png)

![[BCM] [ASMPT] [E3] [BCS] [T2] [CBF] [2] Recovery Strategies](https://no-cache.hubspot.com/cta/default/3893111/4e9f9f5d-21d6-4d00-9dbc-12bea85ba72a.png)

![[BCM] [ASMPT] [E3] [BCS] [T3] [CBF] [2] Minimum Resources Required during a Disaster](https://no-cache.hubspot.com/cta/default/3893111/cb96d738-2a36-4696-a4b1-012b650cb71d.png)

![[BCM] [ASMPT] [E3] [PD] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/c4c7a301-81bb-4f76-b743-8aaf860348ad.png)

![Register [BL-B-3]*](https://blog.bcm-institute.org/hs-fs/hubfs/hub_generated/resized/19a8306f-6b76-45ff-8585-95111f393aeb.png?width=200&height=56&name=19a8306f-6b76-45ff-8585-95111f393aeb.png)

![FAQ [BL-B-3]](https://blog.bcm-institute.org/hs-fs/hubfs/hub_generated/resized/9b7f5669-8ad6-450b-a98f-5f5d49ebfc8e.png?width=150&height=150&name=9b7f5669-8ad6-450b-a98f-5f5d49ebfc8e.png)

![Email to Sales Team [BCM Institute]](https://blog.bcm-institute.org/hs-fs/hubfs/hub_generated/resized/83ae9ad3-affc-416e-8f51-64218d6d98f2.png?width=100&height=100&name=83ae9ad3-affc-416e-8f51-64218d6d98f2.png)