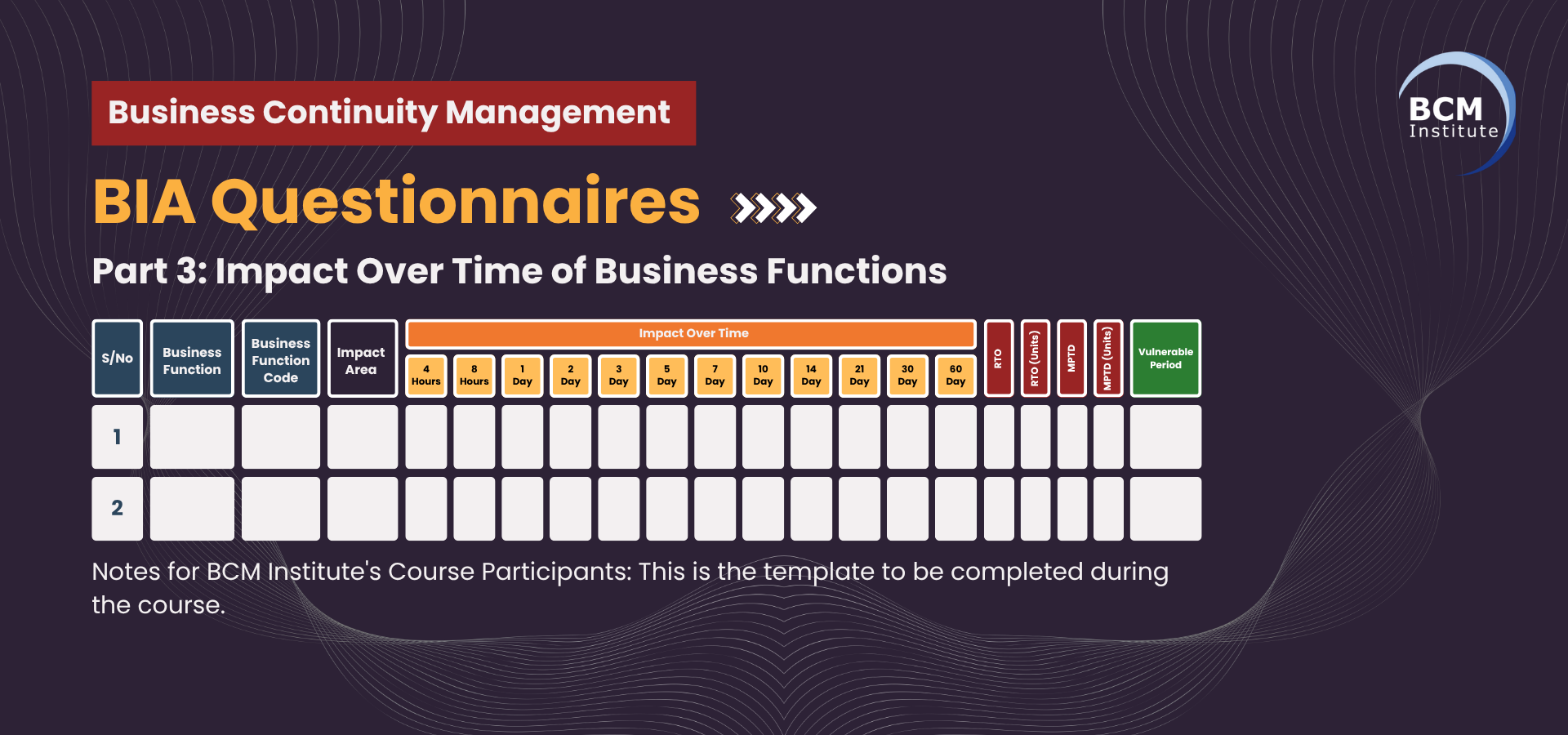

[Business Impact Analysis] [Critical Business Function] [T2] Part 3

BIA Questionnaires

BIA Questionnaires

Part 3: Impact Over Time of Business Functions

CBF-2 Manufacturing and Assembly Operations

In the context of ASMPT’s CBF-2 Manufacturing and Assembly Operations, understanding the impact of disruptions over time is crucial for maintaining operational resilience and compliance with ISO 22301.![[BCM] [ASMPT] [E3] [BIA] [T2] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/93203b93-22b9-4134-8a90-52f0be30fc37.png)

Each sub-critical business function (Sub-CBF) within manufacturing and assembly is interdependent and contributes directly to product delivery, customer commitments, and financial performance.

The “Impact Over Time” analysis allows ASMPT to quantify how quickly the effects of a disruption escalate—from minor inefficiencies to severe production stoppages—across key operational areas such as financial performance, regulatory compliance, customer satisfaction, and reputational impact.

This assessment provides management with clear visibility of:

- The rate at which impacts intensify over hours and days.

- The Recovery Time Objective (RTO) required to restore operations.

- The Maximum Tolerable Period of Disruption (MTPD) beyond which business continuity is threatened.

- The vulnerable periods during which ASMPT is most exposed to operational or market risks.

The following table outlines the impact progression for each Sub-CBF of CBF-2 Manufacturing and Assembly Operations.

Impact Over Time Table – CBF-2 Manufacturing and Assembly Operations

|

Sub-Critical Business Function |

Sub-CBF Code |

Highest-Impact Area |

4 Hr |

8 Hr |

1 Day |

2 Day |

3 Day |

5 Day |

7 Day |

10 Day |

14 Day |

21 Day |

30 Day |

60 Day |

RTO |

MTPD |

Vulnerable Period |

|

1.1 |

Wafer-Level Preparation & Substrate Processing |

Production Output |

2 |

3 |

4 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

1 Day |

3 Days |

Early stage of disruption; impacts production scheduling immediately. |

|

1.2 |

Die Attach & Flip-Chip Bonding |

Financial Loss & Customer Delivery |

2 |

3 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

1 Day |

2 Days |

Highly vulnerable within first 24 hours due to reliance on precision bonding. |

|

1.3 |

Deposition & Metallization |

Compliance & Product Integrity |

1 |

2 |

3 |

4 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

2 Days |

5 Days |

Risk of yield loss and compliance issues increase after 48 hours. |

|

1.4 |

Molding, Trimming & Forming |

Customer Commitment |

1 |

2 |

3 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

2 Days |

5 Days |

Customer delays evident after 2 days; reputational impact rises quickly. |

|

1.5 |

Assembly & Sensor Integration |

Customer Delivery & Market Trust |

2 |

3 |

4 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

1 Day |

3 Days |

Vulnerable during initial 24–48 hours due to product delivery dependencies. |

|

1.6 |

In-Line System Integration & Automation |

Operational Continuity |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

2 Days |

7 Days |

Vulnerable in medium term; automation disruption impacts throughput after 2+ days. |

|

1.7 |

Smart Factory Integration & Open Automation |

Strategic Competitiveness |

1 |

2 |

2 |

3 |

4 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

3 Days |

10 Days |

Long-term impact on competitiveness and efficiency if unresolved. |

| 1.8 |

Process Monitoring, MES & Data Analytics |

Compliance & Decision-Making |

2 |

3 |

4 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

1 Day |

3 Days |

Early vulnerability—decision-making quality deteriorates quickly. |

| 1.9 |

Quality Assurance & End-of-Line Handling |

Compliance & Customer Trust |

2 |

3 |

4 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

1 Day |

2 Days |

Immediate vulnerability—defects and compliance risks emerge within 24 hours. |

Summing Up... Part 3

The analysis of impact over time for ASMPT’s CBF-2 Manufacturing and Assembly Operations highlights how rapidly disruptions can escalate into severe operational, financial, and reputational risks.

- Time sensitivity is critical: Functions like wafer preparation, bonding, assembly, and quality assurance demonstrate immediate impacts within the first 24–48 hours, emphasizing the need for short RTOs.

- Medium- to long-term risks: Areas such as automation integration and smart factory systems have longer tolerances but, if unresolved, significantly weaken ASMPT’s market position and strategic resilience.

- Vulnerability windows: The first 1–3 days are the most critical, where operational disruption quickly translates into customer dissatisfaction, financial penalties, and reputational damage.

This structured assessment ensures ASMPT’s leadership can prioritize recovery strategies, align resources effectively, and safeguard business continuity in alignment with ISO 22301 standards.

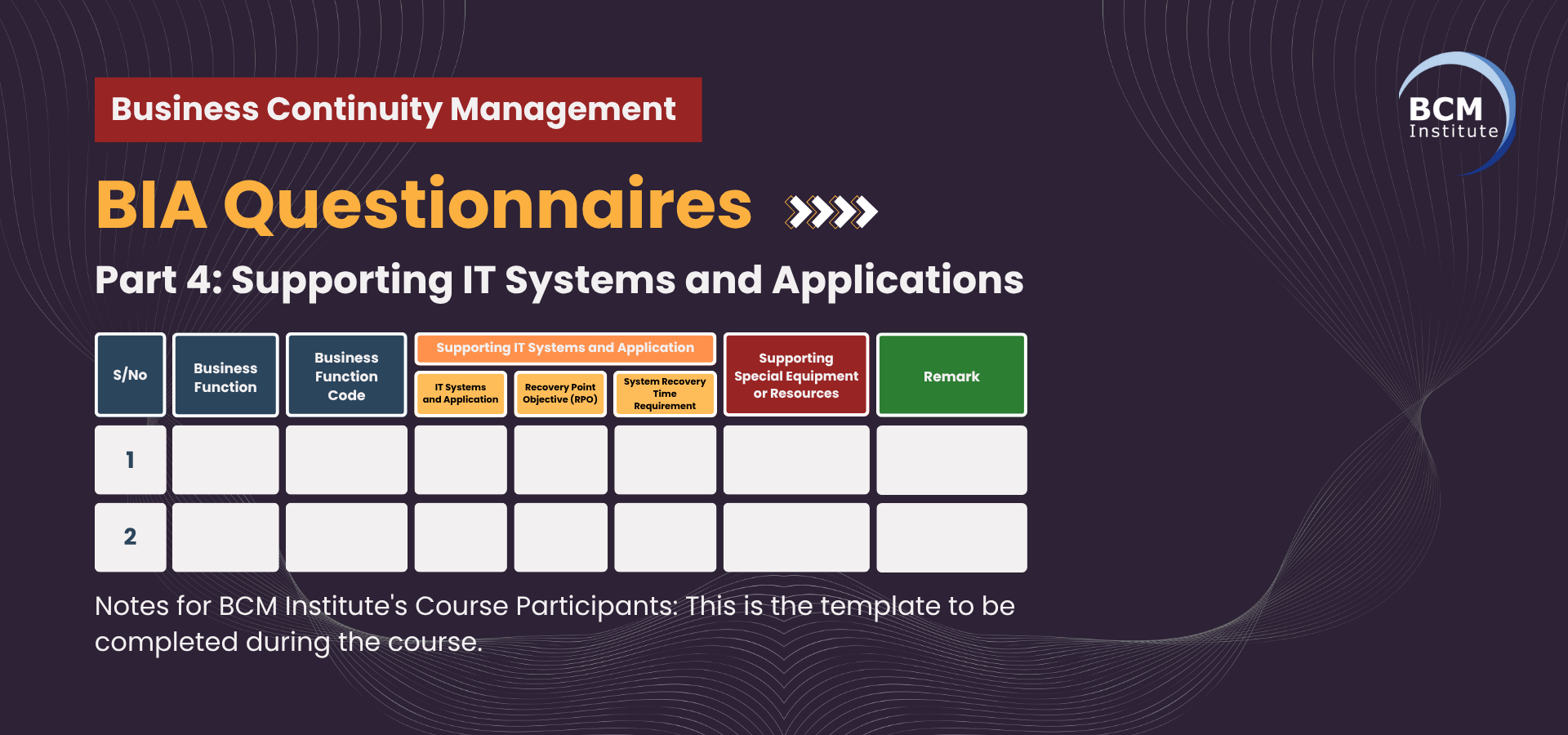

[Business Impact Analysis] [Critical Business Function] [T2] Part 4

BIA Questionnaires

BIA Questionnaires

Part 4: Supporting IT Systems and Applications

CBF-2 Manufacturing and Assembly Operations

The efficiency and resilience of ASMPT’s manufacturing and assembly operations are critically dependent on IT systems, applications, and specialised equipment.

These systems support not only the execution of production processes but also the integration of data-driven automation, quality assurance, and advanced analytics that underpin ASMPT’s leadership in semiconductor and electronics manufacturing.

Business continuity in this context requires a clear understanding of the recovery point objectives (RPO), system recovery time objectives (RTO), and dependencies on specialised resources that enable seamless recovery during disruptions.

The following table outlines the supporting IT systems and applications for each Sub-CBF under CBF-2, together with their continuity requirements.

Table 4: Supporting IT Systems and Applications for CBF-2 Manufacturing and Assembly Operations

|

Sub-CBF Code |

Sub-CBF |

IT Systems and Applications |

RPO |

System RTO |

Supporting Special Equipment or Resources |

Remarks |

|

1.1 |

Wafer-Level Preparation & Substrate Processing |

Manufacturing Execution System (MES), Equipment Control Software, ERP Production Modules |

< 4 hrs |

< 8 hrs |

Precision wafer preparation tools, substrate processing equipment |

Critical for upstream processes; downtime causes cascading delays |

|

1.2 |

Die Attach & Flip-Chip Bonding |

MES, Equipment Control Software, Robotics Programming Tools |

< 2 hrs |

< 4 hrs |

Die bonding machines, flip-chip bonders, robotics arms |

Automation requires synchronization with IT control layers |

|

1.3 |

Deposition & Metallization |

MES, Advanced Process Control (APC), SCADA Systems |

< 4 hrs |

< 8 hrs |

Deposition chambers, metallization systems |

Heavily dependent on environmental controls and system calibration |

|

1.4 |

Molding, Trimming & Forming |

MES, ERP Modules, PLC Systems |

< 8 hrs |

< 12 hrs |

Molding presses, trimming & forming equipment |

Slightly more tolerant of downtime but still impacts production flow |

|

1.5 |

Assembly & Sensor Integration |

MES, ERP, Robotics Control Systems |

< 4 hrs |

< 6 hrs |

Sensor assembly lines, robotic handlers |

Integration stages highly sensitive to automation reliability |

|

1.6 |

In-Line System Integration & Automation |

MES, SCADA, Robotics AI Systems |

< 2 hrs |

< 4 hrs |

Conveyor systems, in-line testers, automation controllers |

Mission-critical due to production continuity dependencies |

|

1.7 |

Smart Factory Integration & Open Automation |

Industrial IoT Platforms, Cloud Integration Tools, MES |

< 2 hrs |

< 4 hrs |

Smart sensors, IoT gateways, industrial networks |

Enables adaptive, real-time decision-making across operations |

| 1.8 |

Process Monitoring, MES & Data Analytics |

MES, Data Analytics Platforms, AI Predictive Tools |

< 1 hr |

< 2 hrs |

Data servers, analytics clusters, monitoring devices |

Immediate recovery required; downtime disrupts overall visibility |

| 1.9 |

Quality Assurance & End-of-Line Handling |

MES, Quality Management Systems (QMS), Automated Optical Inspection (AOI) Software |

< 4 hrs |

< 6 hrs |

AOI machines, test equipment, defect tracking tools |

Impacts product release timelines and customer commitments |

Summing Up ... for Part 4

Supporting IT systems and applications is the backbone of ASMPT’s manufacturing and assembly operations.

Each Sub-CBF has distinct dependencies on specialised IT infrastructure and equipment, with varying RPO and RTO requirements based on its role in the production chain.

High-dependency areas, such as process monitoring (CBF-2.8) and smart factory integration (CBF-2.7), demand near-immediate recovery capabilities due to their role in ensuring real-time decision-making and quality assurance.

By aligning IT recovery priorities with critical business functions, ASMPT ensures that its manufacturing operations remain resilient against disruptions, safeguarding operational continuity, customer commitments, and its position as a global leader in semiconductor and electronics manufacturing solutions.

Time of Business Functions

Time of Business Functions

![[BCM] [ASMPT] [E3] [BIA] [DP] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/449872f6-6f44-40f2-96ad-16b26b246176.png)

![[BCM] [ASMPT] [E3] [BIA] [T1] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/ea7d252e-53e6-4fd2-8bd9-5a9baa0dd532.png)

![[BCM] [ASMPT] [E3] [BIA] [T3 [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/7283dbc8-f3df-4254-99f1-f7ec89c71f08.png)

![[BCM] [ASMPT] [E3] [BCS] [T2] [CBF] [2] Recovery Strategies](https://no-cache.hubspot.com/cta/default/3893111/4e9f9f5d-21d6-4d00-9dbc-12bea85ba72a.png)

![[BCM] [ASMPT] [E3] [BCS] [T3] [CBF] [2] Minimum Resources Required during a Disaster](https://no-cache.hubspot.com/cta/default/3893111/cb96d738-2a36-4696-a4b1-012b650cb71d.png)

![[BCM] [ASMPT] [E3] [PD] [CBF] [2] Manufacturing and Assembly Operations](https://no-cache.hubspot.com/cta/default/3893111/c4c7a301-81bb-4f76-b743-8aaf860348ad.png)

![Register [BL-B-3]*](https://blog.bcm-institute.org/hs-fs/hubfs/hub_generated/resized/19a8306f-6b76-45ff-8585-95111f393aeb.png?width=200&height=56&name=19a8306f-6b76-45ff-8585-95111f393aeb.png)

![FAQ [BL-B-3]](https://blog.bcm-institute.org/hs-fs/hubfs/hub_generated/resized/9b7f5669-8ad6-450b-a98f-5f5d49ebfc8e.png?width=150&height=150&name=9b7f5669-8ad6-450b-a98f-5f5d49ebfc8e.png)

![Email to Sales Team [BCM Institute]](https://blog.bcm-institute.org/hs-fs/hubfs/hub_generated/resized/83ae9ad3-affc-416e-8f51-64218d6d98f2.png?width=100&height=100&name=83ae9ad3-affc-416e-8f51-64218d6d98f2.png)